Strong magnets can be SmCo material which known as rare earth magnets, when the working temperature is above 180℃, its maximum magnetic energy product (BHmax), coercivity, temperature stability and chemical stability are better than those of NdFeB magnets.The maximum energy product (BHmax) of SmCo magnets ranges from 16 MGOe to 32 MGOe, and its theoretical limit is 34 MGOe

The magnetic energy product of ferrite (ceramic) magnet is much lower than that of NdFeB and SmCo, but big ferrite magnets that have powerful magnetism are also called strong magnets.

Besides the above permanent magnetic material for sale, some permanent magnetic assemblies (such as pot magnets, strong fishing magnets, hook magnets) are also called strong magnets.

Here we just introduce some common shapes of neodymium strong magnets, and mainly for sintered neodymium magnets. Because of the high machinability, it can be machined into different shapes and very wide size range is available for each shape. Besides of disc, cylinder, ring and block, neodymium magnets can be machined into some special shapes, for example, countersunk neodymium magnets, sphere neodymium magnets, neodymium cone magnets, neodymium arc & segment magnets, and neodymium convex magnets.

Estimate strong magnets qualified or not, mainly decided by these aspects:

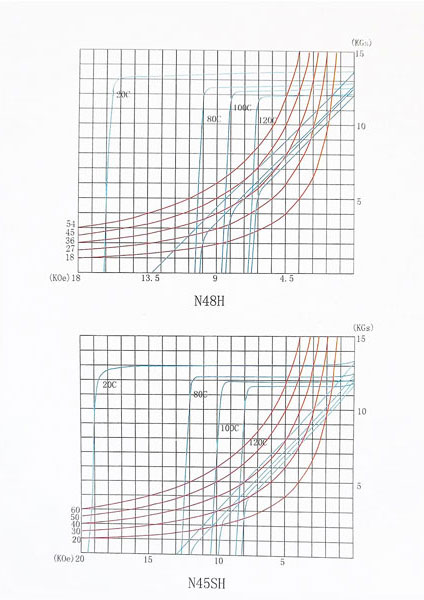

Magnetic performance property: magnetic performance of a permanent strong magnet depends on the formulation, which mainly includes remanence, coercivity, and magnetic energy product. Magnetic properties are the most important aspect of magnets and need professional instrument testing.

Tolerance of the magnets: the tolerance accuracy decided by the machineability of a factory. The machining equipment keeps updated as per market needs. Efficient devices and automation trends of industrial processing, not only meet the need of increasing magnets accuracy but also save manpower and cost.

Appearance of the magnets: appearance evaluation firstly depends on whether there are defects in electroplating; secondly, see if there is a lack of angle in the magnets.

Neodymium strong magnets are more and more used for fabrics, such as neodymium sew-in magnets which can be sewed in curtains, and also sewed in clothes used as waterproof magnetic buttons.

Some small strong magnets are used for decorating fridges or used on fridges or whiteboards as memo magnets.

Strong neodymium magnets for heavy-duty hanging, the big neodymium hook magnets have hundreds of kilograms holding force and are used as magnetic ceiling hooks and wall hooks.

Strong magnets of neodymium are used for magnet fishing and searching, neodymium search magnets have a strong magnetic force and are used to get out the metal objects that fell to the bottom of the river and wall.

Strong neodymium magnets are widely used for producing motors, by using neodymium magnetic tiles, the performance of motors is more stable.

Strong neodymium magnets are used for making speakers, due to the outstanding magnetic performance, strong neodymium magnets make the size of the speaker the smallest.

Neodymium strong magnets are widely used for magnetic separating, by using magnetic separator of neodymium strong magnets, the metal impurities are filtered more thoroughly from food or grain.

Physical Specification Of Neodymium Magnets

|

Parameter |

International Unit |

Standard Data |

|

Curie Temperature(Tc) |

℃ |

310-380 |

|

Maximum Operating Temperature(Tw) |

℃ |

80-230 |

|

Hardness |

Hv |

620 |

|

Electrical Resistivity (ᵨ) |

Ω.cm |

1.8x10⁻⁴ ~2.0x10⁻⁴ |

|

Density(D) |

g/m³ |

7.45~-7.65 |

|

Recoil Permeability(µ rec) |

|

1.05 |

|

Magnetization Field Strength(Hs) |

kA/m |

≧2400 |

|

kOe |

≧30 |

|

|

Bending Strength |

Mpa |

295-345 |

|

Temp. Coefficient of Br |

%℃ |

-0.11~-0.12 |

|

Temp.Coefficient of Hcj |

%℃ |

-0.5~-0.7 |

|

Surface |

Coating |

Thickness (Microns) |

Color |

Resistance |

|

Passivation |

|

1 |

Silver Grey |

Temporary Protection |

|

Nickel |

Ni+Ni |

10-20 |

Bright Silver |

Excellent Against Humidity |

|

Ni+Cu+Ni |

||||

|

Zinc |

Zn |

8-20 |

Bright Blue |

Good Against Salt Spray |

|

C-Zn |

Shinny Color |

Excellent Against Salt Spray |

||

|

Tin |

Ni+Cu+Sn |

15-20 |

Silver |

Superior Against Humidity |

|

Silver |

Ni+Cu+Ag |

10-20 |

Silver |

Superior Against Humidity |

|

Gold |

Ni+Cu+Au |

10-20 |

Gold |

Superior Against Humidity |

|

Copper |

Ni+Cu |

10-20 |

Gold |

Temporary Protection |

|

Epoxy |

Epoxy |

15-25 |

Black,Red,Grey |

Excellent Against Humidity&Salt Spray |

|

Ni+Cu+Epoxy |

||||

|

Zn+Epoxy |

||||

|

Parylene |

Parylene |

5-20 |

Grey |

Excellent Against Humidity,Salt Spray,Superior Against Solvents,Gases, Fungi and Bacteria,FDA Approved |

|

Chemical |

Ni |

10-20 |

Silver Grey |

Excellent Against Humidity |

Every grade of neodymium magnet has a specific maximum working temperature as the below list,the best temperature should not exceed the maximum of the neodymium magnets.

|

Neodymium Magnet Material Grade |

Maximum Working Temp. |

Curie Temp. |

|

N |

176°F (80°C) |

590°F (310°C) |

|

NM |

212°F (100°C) |

644°F (340°C) |

|

NH |

248°F (120°C) |

644°F (340°C) |

|

NSH |

302°F (150°C) |

644°F (340°C) |

|

NUH |

356°F (180°C) |

662°F (350°C) |

|

NEH |

392°F (200°C) |

662°F (350°C) |

|

NAH |

428°F (220°C) |

662°F (350°C) |

The maximum working temperature listed above are values just associated with each grade of permanent magnet materials. Actual values in your application may vary depend other factors, including the shape of the magnet, the performance coefficient or load line, and how it is used in a magnetic circuit.

Grinding machining: for sintered NdFeB magnets, grinding machine needed for the surface of rough delivered magnets. Common used grinding machine methods for block NdFeB magnets are plane grinding, two end face grinding, inner circle grinding, out circle grinding. Cylinder NdFeB magnets adopt coreless grinding and two end plane grinding. Irregular magnets (arc magnets and segment magnets) adopt multi-station grinding.

Drilling machining: processing cylinder magnets and block magnets into round tube magnets and block magnet tubes.

The safety distance is just demanded for ferromagnetic objects and electronics. Ferromagnetic objects and electronics should be placed outside the magnetic field of the neodymium magnets.

The strongest magnet on earth is the strong neodymium magnet which has the highest magnetic energy.