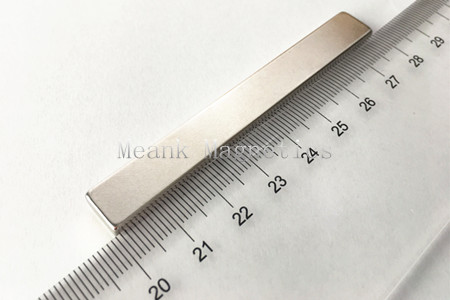

In the ever-evolving food industry, ensuring both hygiene and efficiency in processing is paramount to meet the strict quality standards and to maintain consumer trust. The emergence of PTFE coated magnets has revolutionized the way food is handled and processed. With their exceptional non-stick properties and resistance to corrosive substances, PTFE coated magnets, such as those produced by BeiLun Meank, are transforming the food industry by enhancing hygiene and improving operational efficiency.

Enhanced Hygiene

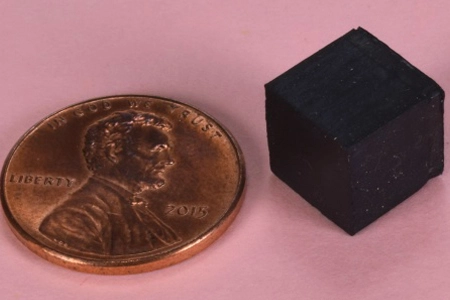

PTFE (polytetrafluoroethylene) is a synthetic material known for its excellent resistance to chemical attack and its non-stick properties. When magnets used in food processing are coated with PTFE, they become highly resistant to corrosive substances and food residues. This prevents the accumulation of contaminants and ensures a hygienic environment throughout the processing stages.

Easy Cleaning

Due to the non-stick surface properties of PTFE, any food residues or contaminants that come into contact with PTFE coated magnets can be easily wiped off, minimizing the risk of bacterial growth. This makes the cleaning process more efficient and time-saving, contributing to improved operational productivity.

Corrosion Resistance

PTFE is highly resistant to corrosion, even when exposed to aggressive cleaning chemicals or acidic food ingredients. Therefore, magnets that are coated with PTFE have a longer lifespan and require less frequent replacement or maintenance, reducing downtime and overall costs.

Temperature Stability

PTFE also exhibits excellent thermal stability, allowing the coated magnets to withstand high temperatures without deteriorating or releasing any harmful substances into the food. This characteristic is particularly important in food processing applications that involve heat treatments.

Meat Processing

PTFE coated magnets play a critical role in efficient removal of metal contaminants, such as iron or stainless steel particles, from meat products during processing. These magnets can be easily integrated into processing equipment like conveyors and separators, ensuring that the final products are free from any foreign metallic substances.

Dairy Processing

PTFE coated magnets find ample use in the dairy industry for the removal of ferrous contaminations from liquid or powdered products, like milk, cream, cheese, or whey. The non-stick properties of PTFE facilitate easy cleaning, preventing bacterial growth and maintaining the product's integrity.

Among the leading manufacturers of PTFE coated magnets, BeiLun Meank stands out for its commitment to excellence and product innovation. With a strong focus on quality control and continuous improvement, BeiLun Meank offers a diverse range of PTFE coated magnets tailored to meet the demanding requirements of the food industry. Their magnets undergo comprehensive testing, ensuring superior performance, efficiency, and longevity.

As the food industry undergoes a revolution towards improved hygiene and processing efficiency, PTFE coated magnets have emerged as a game-changer. Combining excellent non-stick properties, resistance to corrosion, and easy cleaning, PTFE coated magnets from BeiLun Meank offer a reliable solution to enhance hygiene and efficiency throughout the food processing stages. By integrating these magnets into various processing equipment, the food industry can ensure the production of safe, high-quality products that meet consumer demands.