What is the production process of China's NdFeB magnets?

1. Raw material preparation and pre-processing of China NdFeB magnets:

Process introduction: Pre-processing of raw materials, including weighing, crushing, cutting, and rust removal.

Process equipment: Steel bar cutting machine, drum polisher, etc.

2. Melting of China NdFeB magnets:

Process introduction: The pre-processed raw materials such as praseodymium, neodymium, pure iron, and boron iron are proportionally mixed and added to a vacuum melting furnace for high temperature melting and casting under the protection of argon to ensure uniform product composition, high crystalline orientation and good structural consistency, and avoid the formation of α-Fe.

Process equipment: Vacuum melting furnace.

3. Hydrogen decarburization of China NdFeB magnets:

Process introduction: Hydrogen decarburization (HD) process utilizes the hydrogen absorption characteristics of rare earth metal intermetallic compounds. The NdFeB alloy is placed in a hydrogen environment, and hydrogen infiltrates the alloy along the rich neodymium phase layer to cause expansion, cracking and fragmentation, ensuring the integrity of the main phase crystal grains and rich neodymium grain boundary phase. The HD process greatly increases the porosity of the NdFeB flakes, improves the efficiency of airflow milling, and reduces production cost.

Process equipment: Vacuum hydrogen treatment furnace.

4. Powdering of China NdFeB magnets:

Process introduction: Airflow milling powdering uses the high-speed collision of the material itself for crushing, with no wear or pollution to the inner wall of the grinding chamber, and can efficiently prepare powder.

Process equipment: Airflow mill.

5. Forming and orientation of China NdFeB magnets:

Process introduction: Orientation is used to align the easy magnetization direction c-axis of disoriented powder particles to the same direction, in order to obtain maximum residual magnetism. The main purpose of pressing is to press the powder into a certain shape and size, and to maintain the crystal orientation obtained in the magnetic field orientation as much as possible. We use a molding magnetic field press and isostatic press for secondary molding. For irregular magnets, we use special mold tools for direct molding, and the surface treatment of the sintered magnets only needs to be slightly processed before they can be put into use, greatly saving material and subsequent processing costs.

Process equipment: Magnetic field press, isostatic press.

6. Sintering of China NdFeB magnets:

Process introduction: Sintering is a simple and inexpensive way to change the microstructure of materials to improve their magnetic properties. Sintering is the final forming process and has a very important influence on the density and microstructure of the magnet.

Process equipment: Vacuum sintering furnace.

7. Machining of China NdFeB magnets:

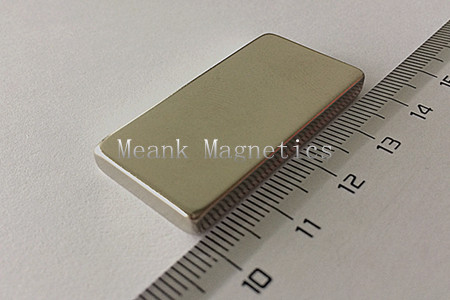

Process introduction: After sintering, the NdFeB magnet is a blank and needs to be further machined to obtain various sizes, shapes, and dimensions of products. Due to the brittleness and poor mechanical properties of NdFeB magnets, only grinding and cutting can be used for machining.

Process equipment: Surface grinder, double-end surface grinder, chamfering machine.

8. Surface treatment of China NdFeB magnets:

Process introduction: Surface treatment of various shaped rare earth permanent magnets, such as electrophoresis, galvanizing, electroplating of nickel, nickel-copper-nickel, and phosphating, to ensure the appearance and corrosion resistance of the product.

9. Finished product inspection and packaging of China NdFeB magnets:

Process introduction: Various magnetic properties, corrosion resistance, and high-temperature performance of the product are tested, and then packaged to meet the various needs of customers.