In the rapidly evolving world of technology, innovation is the name of the game. Electronics manufacturers are constantly searching for new ways to improve their products and stay ahead of the competition. One such innovation that has recently gained traction is the magnetic balls factory.

The BeiLun Meank brand has been at the forefront of this revolution, leading the way with their cutting-edge magnetic balls factory. This state-of-the-art facility has revolutionized electronics manufacturing, offering a host of advantages for both manufacturers and consumers.

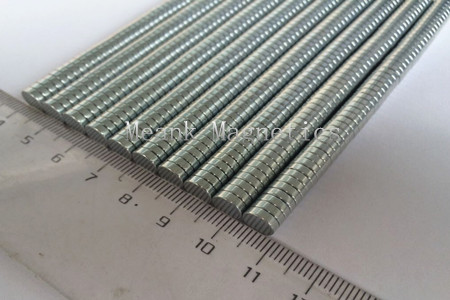

Magnetic balls, also known as magnetic spheres or neodymium balls, offer several unique properties that make them invaluable in the electronics industry. These tiny, powerful magnets can be utilized in various applications, from securing components to improving overall performance.

At the magnetic balls factory, these tiny magnets are carefully manufactured and precisely calibrated to meet specific requirements. With their strong magnetic pull, they provide a secure and reliable connection for delicate electronic components, ensuring consistent performance and longevity.

Traditional methods of electronics assembly often involve soldering, which can be time-consuming and prone to human error. With the introduction of the magnetic balls factory, manufacturers now have a more efficient and precise assembly method at their disposal.

By incorporating magnetic balls into the assembly process, manufacturers can eliminate the need for soldering. This not only reduces production time and costs but also minimizes the risk of damaged components. The magnetism of the balls allows for easy placement and alignment, ensuring an accurate and reliable connection every time.

The use of magnetic balls in electronics manufacturing offers unparalleled design flexibility. These magnetic spheres can be incorporated into various electronic devices, from smartphones and laptops to medical equipment and automotive components.

Their small size and magnetic properties make them ideal for space-constrained designs, allowing for more compact and sleek products. Additionally, the magnetic balls' versatility enables the creation of modular components, facilitating easy repair and upgradeability.

Quality control is of utmost importance in electronics manufacturing. Defective components or poor connections can lead to product failures, warranty claims, and a damaged reputation. The magnetic balls factory plays a critical role in ensuring the highest standards of quality and reliability.

BeiLun Meank's magnetic balls factory utilizes strict quality control measures to guarantee that each magnetic ball meets precise specifications. By employing advanced testing techniques, manufacturers can have confidence in the performance, durability, and consistency of the magnetic spheres.

In conclusion, the introduction of the magnetic balls factory has brought about significant innovations in electronics manufacturing. BeiLun Meank's leadership in this space has revolutionized the industry, offering enhanced efficiency, precision, flexibility, and reliability. As technology continues to advance, magnetic balls will undoubtedly play an even more prominent role in shaping the future of electronics.