Ferrite magnets are actually relatively large when they are produced, so manufacturers will definitely carry out cutting and other processes during production, but what should we do? In fact, you can learn about this knowledge from the following aspects. If you are interested, you can take a look. We believe it will be very helpful to you.

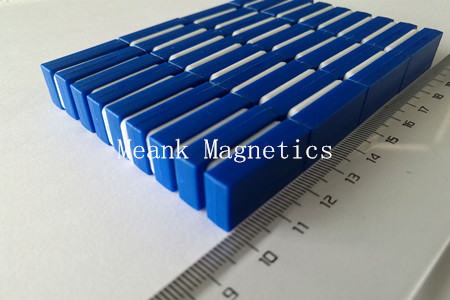

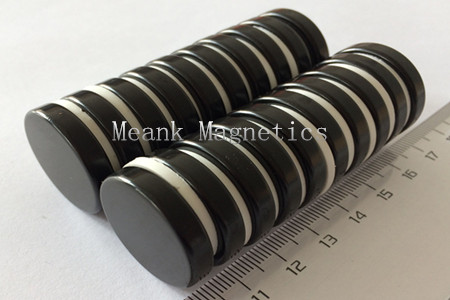

Ferrite cutting magnets are mainly square, circular, cylindrical and arcuate magnets used in electromagnetic coils, and samples are also purchased and customized with unique specifications.

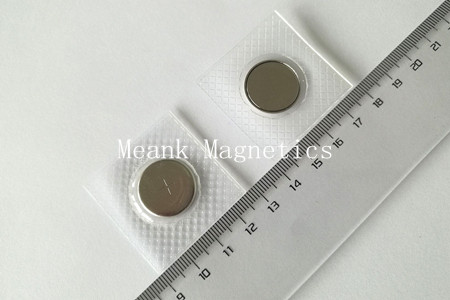

It is used for door magnetic alarms, sensory components, magnetic suction seats, door stops, automatic components, DIY components, health magnetic therapy, magnetic equipment, magnetic chip separators, etc.

With the improvement of cutting strength, the current small size of the ferrite cutting magnet that can be cut is L2xW2x0.8mmT, which can be cut and manufactured according to the size specified by the customer.

The ferrite cutting magnet is made by cutting the block rough embryo, and the raw material is strontium (Sr) ferrite, the molding time is longer, but the density is higher. The comment is that the larger the rough block material, the better, but due to the pressure limitation of the machine itself and the consideration of the yield improvement, the size of the control block material is L220xW150x25.4mmT.

The ferrite permanent magnet itself can only process its outer diameter and thickness, but cannot be divided. If it is divided, its original function will change, and a weak magnetic phenomenon will occur. The outer diameter and thickness are mostly processed by water grinding. The appearance will change, but the original form will not change.

Coarse embryo block ⟶ heating ⟶ sticking ⟶ cutting ⟶ surface grinding ⟶ cleaning ⟶ magnetizing ⟶ testing ⟶ packaging ⟶ shipping.

Now we have introduced the relevant knowledge points to everyone, and everyone should understand it later! If you need to buy NdFeB magnets, ferrite magnets and other products, you can contact us directly.

We have been engaged in the production of rare earth neodymium magnets for more than 10 years. After years of development in the field of rare earth permanent magnets, we not only produce the highest grade NdFeB power magnets, but also various magnet components (such as holding magnets, pot magnets, separation magnets, and other magnet magnetic tools).