In today's modern manufacturing industry, achieving a flawless production process is paramount. Companies constantly search for innovative solutions to enhance efficiency, reduce production costs, and improve the overall quality of their products. One such solution that has gained significant attention in recent years is the utilization of PTFE coated magnets. With their exceptional sticking power and numerous advantageous properties, PTFE coated magnets have become a game-changer for manufacturers across various industries.

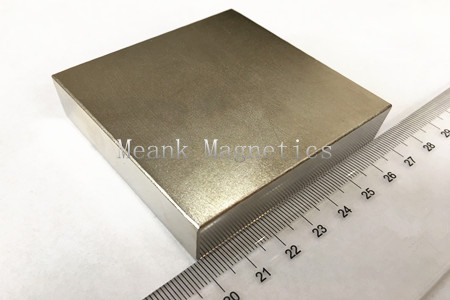

At the forefront of this revolutionary technology is BeiLun Meank, a highly reputable brand known for its high-quality PTFE coated magnets. Known for their durability and excellent performance, BeiLun Meank's PTFE coated magnets have become an indispensable component in many manufacturing processes. Let's delve deeper into the features and benefits of these remarkable magnets.

One of the most remarkable qualities of PTFE coated magnets is their exceptional sticking power. The PTFE (polytetrafluoroethylene) coating significantly reduces the friction between the magnet and the surface it is applied to, resulting in a stronger magnetic attraction. This increased sticking power ensures that the magnet remains securely in place, even in challenging environments or when subjected to vibrations, preventing any potential disruptions in the manufacturing process.

PTFE coated magnets exhibit exceptional resistance to chemicals and corrosion, making them ideal for use in diverse industrial settings. These magnets can withstand harsh conditions, including exposure to acids, alkalis, solvents, and various corrosive agents. This quality extends the lifespan of the magnets, ensuring longevity and consistent performance, even when used in demanding manufacturing environments.

Manufacturers often face challenges when it comes to maintaining the integrity of magnets in extreme temperature conditions. PTFE coated magnets excel in both high and low-temperature environments, enabling their use in a wide range of manufacturing processes. These magnets can withstand temperatures as low as -200°C and as high as 260°C, making them exceptionally versatile and reliable.

In manufacturing processes, cleanliness and hygiene play a crucial role in maintaining product quality. PTFE coated magnets are non-stick, allowing for easy cleaning and preventing the buildup of contaminants. This feature ensures that the magnets maintain their optimum performance, minimizes the risk of product contamination, and reduces downtime associated with cleaning and maintenance.

In conclusion, PTFE coated magnets have become a necessity in modern manufacturing due to their exceptional sticking power and numerous advantageous properties. BeiLun Meank, a trusted brand in the industry, offers high-quality PTFE coated magnets that meet the demands of various industrial applications. With their unmatched resistance to chemicals, corrosion, and extreme temperatures, these magnets provide manufacturers with a reliable solution to streamline their production processes and enhance product quality. Incorporating PTFE coated magnets from BeiLun Meank into manufacturing operations can lead to improved efficiency, reduced costs, and increased customer satisfaction. Invest in the outstanding sticking power of PTFE coated magnets to catapult your manufacturing processes into the future.