At present, the production processes of all kinds of magnets are mainly sintering, casting, bonding and hot pressing. One of the processes may be suitable for the production of several kinds of magnets, but in the actual production process, some processes and details should be adjusted and improved according to the characteristics of the magnets themselves. The following several kinds of production processes are introduced one by one. Among them, the sintering process is the most widely used production process, suitable for sintering NdFeB magnets,

permanent ferrite magnet, Sm-Co magnets and sintered alnico magnets. Cast technology is mainly used to produce cast Al-Ni-Co magnets. The bonding process is mainly used in the production of various kinds of bonded magnets, such as bonded NdFeB, bonded Samarium Cobalt, Rubber Magnetic, etc. The hot deformation process is mainly used in the production of hot pressed and hot deformed NdFeB

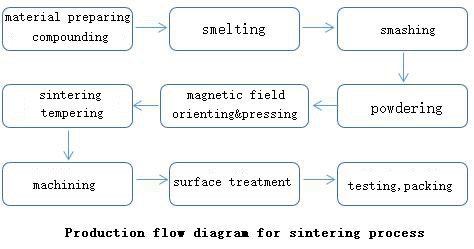

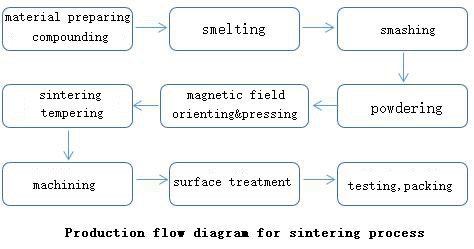

Sintering process of permanent magnets

The sintering process is a method of powder metallurgy, which is the most widely used production process at present. It is suitable for the production of sintered magnets such as permanent magnet neodymium, permanent magnet ferrite, magnet samarium cobalt and sintered Al-Ni-Co.The production flow diagram is shown in figure 1.

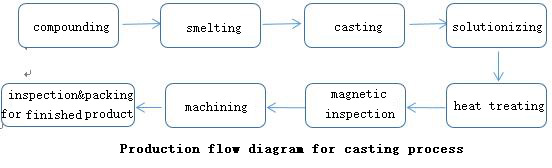

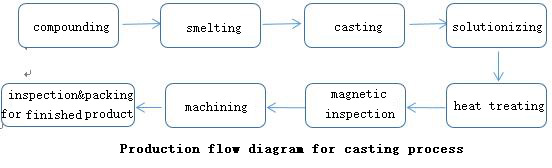

casting technique for permanent magnets

Casting is the process of melting a solid metal into a liquid and pouring it into a mold of a particular shape to be solidified and formed. For permanent magnets, the casting process is mainly used to produce cast Al-Ni-Co magnets. Compared with sintered AlNiCo magnets, cast AlNiCo magnets have higher magnetic properties and can be processed into different sizes and shapes. The process of sintered Al-Ni-Co is simple, the tolerance of blank size is small, and the machinability is good. The schematic diagram of the production process is shown in figure-2

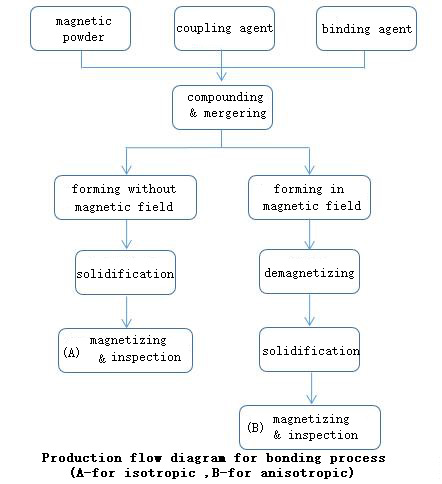

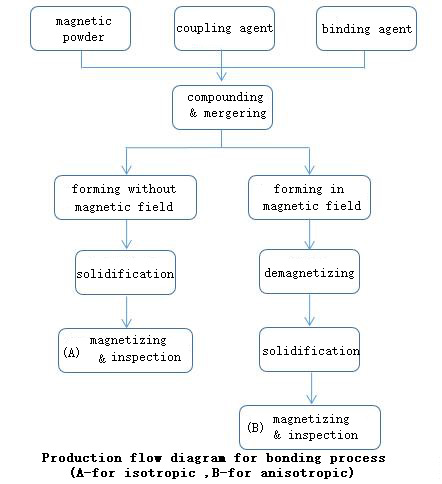

The Bonding process of permanent magnets

The bonding process is a production process for the preparation of composite permanent magnetic material by compacting, extrusion and injection molding by mixing the powder of permanent magnetic material with a certain magnetic property with the adhesive and other additives in a certain proportion. Compared with sintered permanent magnets and cast permanent magnets, bonded permanent magnets have the advantages of high dimensional accuracy, no deformation and no need for secondary processing;Products of various shapes, such as strip, flake, tubular, annular or other complex shapes, depending on the actual use of the product; Easy to automate production in large quantities;And the mechanical strength of the product is high. Its shortcoming is that the magnetic property is low and the use temperature is not high. The key technologies in the process of bonding are the preparation of magnetic powder, the selection of coupling agent and adhesive, the amount of binder, the pressure of molding and the intensity of orientation magnetic field, etc. The manufacturing methods of magnetic powder used for bonding NdFeB include melt rapid quenching, HDDR, mechanical alloying and gas spraying. Among them, HDDR method is popular at present. The production flow diagram of the bonding process is shown in figure-3.

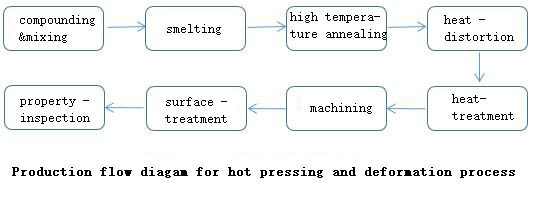

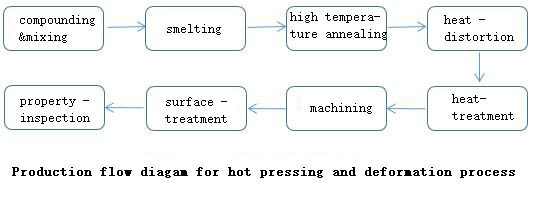

Hot pressing hot deformation technology for permanent magnets

The hot pressing process is another process for producing

neodymium pot magnet. Isotropic neodymium magnets and anisotropic neodymium magnets can be produced by this process. The NdFeB magnets produced by this process have high magnetic properties and the radial maximum magnetic energy product can reach 240 ~ 360 kJ/m3. The magnetic ring is nanocrystalline structure, high density, epoxy resin electrophoretic coating, good corrosion resistance. The hot pressing anisotropic radiation oriented ring magnet is mainly used in EPS motor, servo motor, electric tool motor, and all kinds of direct current. The flow chart of hot pressing and deformation process is as follows: