Neodymium magnets, also known as NdFeB magnets, are the strongest permanent magnets available today. Since their commercial introduction in the 1980s, they have transformed industries ranging from renewable energy and electric vehicles to electronics, automation, and medical devices. But what exactly makes neodymium magnets so special compared to other types of magnets?

The most distinctive feature of neodymium magnets is their extraordinary magnetic force.

Made from an alloy of neodymium (Nd), iron (Fe), and boron (B)

Exhibit extremely high magnetic energy density

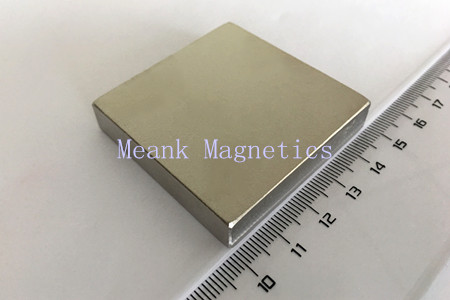

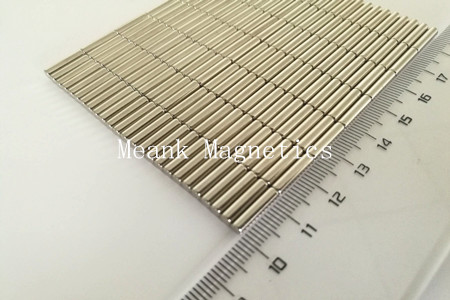

Can generate strong magnetic fields even in very small sizes

In technical terms, neodymium magnets have a maximum energy product (BHmax) of up to 52 MGOe, far exceeding ferrite or Alnico magnets. This allows designers to reduce component size and weight without sacrificing performance.

Because of their strength, neodymium magnets enable miniaturization:

Smaller motors with higher torque

Compact sensors and actuators

Lightweight yet powerful magnetic assemblies

This is especially critical in applications such as electric motors, drones, consumer electronics, and medical instruments, where space efficiency directly affects performance and cost.

Neodymium magnets are used in almost every advanced industrial sector:

Electric vehicles (EVs) – high-efficiency traction motors

Wind turbines – direct-drive generators

Industrial automation – servo motors, linear actuators

Electronics – speakers, headphones, hard drives

Medical devices – MRI systems, precision instruments

Renewable energy & robotics – compact, high-power solutions

Their ability to maintain strong magnetic fields under load makes them ideal for high-performance motion control systems.

Neodymium magnets are available in various grades (e.g., N35, N42, Neodymium Magnets N52), which indicate magnetic strength. They can also be engineered to withstand different operating temperatures:

Standard grades: up to ~80 °C

High-temperature grades (H, SH, UH, EH): up to 200–230 °C

This flexibility allows engineers to select magnets tailored to specific thermal and mechanical requirements.

Because neodymium magnets contain iron, they are prone to corrosion. To improve durability, they are typically coated with:

Nickel-Copper-Nickel (NiCuNi)

Zinc

Epoxy or phosphate coatings

These coatings protect the magnet in humid, corrosive, or outdoor environments, extending service life.

In motors and generators, neodymium magnets enable:

Higher power density

Improved efficiency

Lower energy losses

This is why they are critical in energy-efficient technologies, such as EV drivetrains and renewable power systems, where efficiency directly impacts operating costs and carbon emissions.

| Magnet Type | Strength | Size Efficiency | Cost | Temperature Resistance |

|---|---|---|---|---|

| Neodymium | ★★★★★ | ★★★★★ | Medium–High | Medium–High |

| Ferrite (Ceramic) | ★★ | ★★ | Low | High |

| Alnico | ★★★ | ★★ | High | Very High |

| Samarium Cobalt | ★★★★ | ★★★★ | Very High | Excellent |

Neodymium magnets offer the best overall balance of strength, size, and performance, making them the preferred choice in modern engineering.

As industries move toward electrification, automation, and sustainability, neodymium magnets play a critical role by enabling:

Smaller and lighter machines

Higher efficiency systems

Advanced motion and power control

Their unique combination of strength, versatility, and efficiency makes them indispensable in today’s high-tech world.

What makes neodymium magnets so special is not just their strength, but how that strength enables innovation across multiple industries. From electric vehicles and renewable energy to precision automation and electronics, neodymium magnets deliver unmatched performance in compact forms—making them a cornerstone of modern engineering and manufacturing.