Magnets are an essential part of modern technology, from everyday household items to advanced electronics. However, not all magnets are created equal. Two common types you might encounter are neodymium magnets and normal magnets (such as ceramic or alnico magnets). Understanding their differences is crucial for selecting the right magnet for your application.

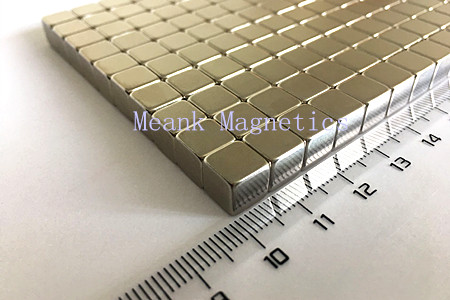

Neodymium magnets are made from an alloy of neodymium, iron, and boron. This combination allows them to produce an exceptionally strong magnetic field despite their small size.

Normal magnets include:

Ceramic (ferrite) magnets: Made from iron oxide combined with barium or strontium carbonate.

Alnico magnets: Made from aluminum, nickel, and cobalt alloys.

Flexible magnets: Made from rubber or plastic mixed with magnetic powders.

One of the most significant differences is strength.

Neodymium magnets are up to 10 times stronger than ceramic magnets of the same size.

Normal magnets are generally weaker and often require a larger size to achieve comparable magnetic force.

This makes neodymium magnets ideal for applications where high performance is needed in a compact form.

Due to their superior strength, neodymium magnets can be made very small while still maintaining a powerful magnetic field. Normal magnets, such as ferrite or alnico, often need to be larger to generate the same magnetic force, making them less suitable for compact devices.

Neodymium magnets are sensitive to high temperatures and may lose their magnetism above 80–200 °C depending on the grade.

Ceramic and alnico magnets have better temperature resistance. Alnico, for example, can withstand temperatures up to 500 °C, making it suitable for high-temperature applications.

Neodymium magnets are brittle and prone to corrosion. They are typically coated with nickel, zinc, or epoxy to protect them.

Normal magnets like ferrite are naturally corrosion-resistant, while flexible magnets are durable but less powerful.

Electric motors and generators

Hard disk drives

Magnetic separators

Medical devices and sensors

Refrigerator magnets

Speakers and microphones

Toys and educational kits

High-temperature industrial applications

Choosing the right magnet depends on your specific needs. If you require high strength in a compact size, neodymium magnets are the best choice. For high-temperature stability or cost-sensitive applications, normal magnets like ceramic or alnico may be more suitable. Understanding these differences ensures optimal performance and durability for your projects. Contact us!