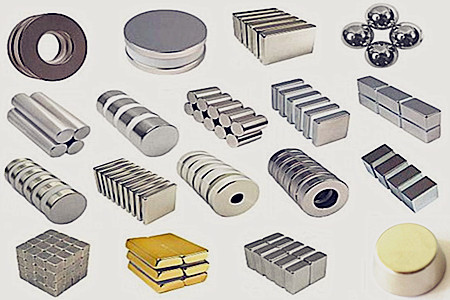

Meank has been worked on supplying permanent magnets (including rare earth neodymium magnets, SmCo magnets, ferrite magnets and AlNiCo, rubber magnets) and magnetic assemblies (mainly involve neodymium magnet assemblies and magnet assemblies of ferrite). The magnetic parameters of our permanent magnets are kept at the upper limit level. The plating thickness of our neodymium magnets and pot magnets is up to the standard, the corrosion resistance of the magnet product is ensured. We have strong ability to process irregular neodymium magnets and SmCo magnets which is difficult for other manufacturer. The tolerance of rare earth magnet is strictly controlled in the range of industry standard. Many kinds of magnetic assemblies available for various magnetic applications of holding, clamping, fishing, mounting, hanging, lifting, separating.