In laboratories and manufacturing facilities, there is often a need for strong magnets that can withstand various chemical environments. This is where PTFE coated magnets come into play. PTFE (polytetrafluoroethylene) is a versatile material known for its non-stick properties and excellent chemical resistance. In this blog, we will explore the benefits of using PTFE coated magnets in chemical environments and their impact on laboratory and manufacturing processes.

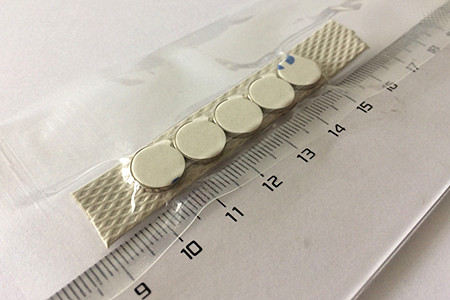

PTFE coated magnets, such as those manufactured by BeiLun Meank, are powerful magnets that have been encapsulated in a protective layer of PTFE. PTFE is a synthetic fluoropolymer that is resistant to a wide range of chemicals, making it an ideal choice for applications where magnet corrosion is a concern. The PTFE coating acts as a barrier between the magnet and surrounding chemicals, ensuring long-term durability and performance.

PTFE coated magnets have excellent chemical compatibility, which allows them to withstand highly corrosive substances without deteriorating. The PTFE coating is resistant to acids, bases, solvents, and other harsh chemicals commonly found in laboratories and manufacturing environments. This compatibility ensures that the magnets remain functional, maintaining their magnetic strength and structural integrity even in challenging conditions.

Laboratories often handle various chemicals that can react with magnets, leading to corrosion and reduced functionality. By using PTFE coated magnets, laboratories can ensure the longevity of their magnetic equipment. The PTFE coating provides an additional layer of protection against chemical exposure, preventing damage to the magnet. This not only saves costs associated with magnet replacement but also minimizes the risk of contamination in experiments and manufacturing processes.

Manufacturing processes often involve the use of corrosive chemicals or abrasive environments. PTFE coated magnets can be employed in a wide range of manufacturing applications, including material handling, conveyor systems, separators, and even magnetic stirrers in mixing processes. The chemical resistance of PTFE coated magnets allows for reliable and efficient operation in demanding industrial settings, reducing downtime and maintenance requirements.

In conclusion, PTFE coated magnets offer significant advantages in both laboratory and manufacturing environments by providing resistance to chemicals that could adversely affect the performance of regular magnets. The protective PTFE coating ensures the longevity and reliability of the magnets, limiting the need for frequent replacements. By using PTFE coated magnets, laboratories and manufacturing facilities can protect their investment and enhance the overall efficiency of their operations. With chemicals compatibility being a crucial factor, PTFE coated magnets from BeiLun Meank prove to be a reliable choice for various applications, ensuring optimal performance in even the most challenging chemical environments.