In recent years, the automotive industry has witnessed advancements in materials and technology that have revolutionized both design and manufacturing processes. Amongst these innovations, flexible rubber magnets have emerged as a game-changer, offering countless possibilities in automotive applications. This blog explores how BeiLun Meank, a leading manufacturer in the industry, is spearheading the use of flexible rubber magnets in automotive design and manufacturing.

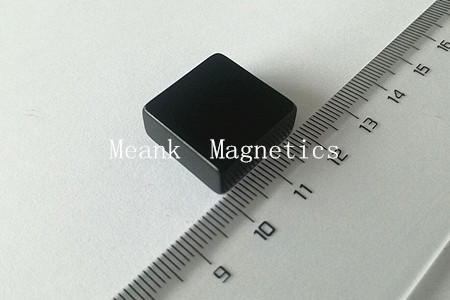

Flexible rubber magnets are an incredibly versatile material that can be easily molded into various shapes and sizes, thus accommodating the intricate design requirements of the automotive industry. These magnets possess unique attributes, such as flexibility, lightweight, and strong adhesion properties, making them ideal for numerous applications.

Flexible rubber magnets play a crucial role in improving vehicle performance and safety. One such application is in the manufacture of gaskets and seals, which are essential for preventing water and dust ingress. These magnets ensure a secure seal, contributing to enhanced cabin insulation, noise reduction, and overall occupant comfort.

Moreover, flexible rubber magnets are also extensively utilized in sensor applications, including proximity sensors, speed sensors, and position sensors. By leveraging the magnet's magnetic properties, automotive manufacturers can enhance the accuracy and reliability of critical safety features, such as anti-lock braking systems (ABS) and airbag deployment systems.

BeiLun Meank's flexible rubber magnets have significantly simplified several automotive manufacturing processes. These magnets can be easily integrated into assembly line tools and equipment, such as robotic arms, to optimize efficiency, reduce downtime, and improve production output. The magnets' ability to adhere to metal surfaces allows for quick, tool-free mounting and repositioning, eliminating the need for traditional fastening methods and reducing manual intervention.

With the automotive industry's growing emphasis on sustainability, flexible rubber magnets offer eco-friendly solutions. The magnets are recyclable and contribute to lightweight vehicle components, resulting in improved fuel efficiency and reduced emissions. They also support the growing trend of electric vehicles by enabling the efficient packaging of electric motors, batteries, and powertrain components.

As the automotive industry continues to evolve, BeiLun Meank's flexible rubber magnets are playing a pivotal role in transforming the design and manufacturing landscape. Their versatility, performance-enhancing capabilities, streamlining advantages, and environmental benefits are propelling the automotive industry forward. With this innovative material, the future of automotive design and manufacturing is undoubtedly on the move towards greater efficiency and sustainability.