In the world of aerospace and industrial engineering, innovation and efficiency are key drivers of success. As technology continues to advance at a rapid pace, engineers and manufacturers are constantly on the lookout for ways to improve the performance and durability of their products. One such innovation that is making waves in the industry is the use of Teflon coated magnets. In this blog, we will explore the benefits and applications of Teflon coated magnets, and how they are shaping the future of aerospace and industrial engineering.

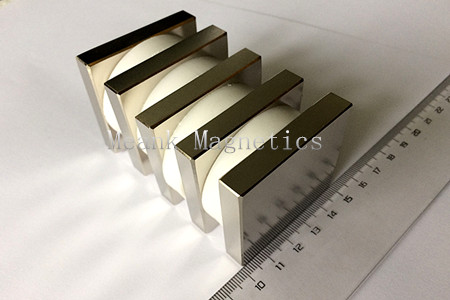

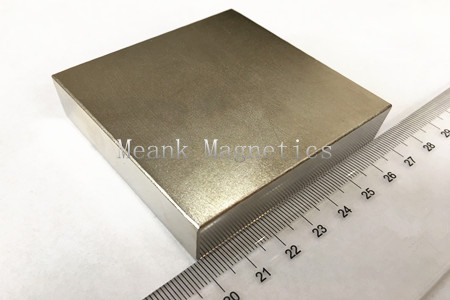

Teflon coated magnets, also known as PTFE (polytetrafluoroethylene) coated magnets, are a recent addition to the engineering world. The use of Teflon coating on magnets offers several advantages. Teflon is a non-stick, low-friction material that provides excellent resistance to chemicals, heat, and wear. These properties make Teflon coated magnets ideal for applications where durability, thermal stability, and performance are essential.

In the aerospace industry, Teflon coated magnets have proven to be a game-changer. The high temperature resistance of Teflon allows these magnets to withstand extreme conditions, making them suitable for aerospace applications. From securing components during flight to controlling moving parts, Teflon coated magnets play a crucial role in improving the efficiency and reliability of aircraft systems. Whether it is in avionics or propulsion systems, these magnets provide dependable performance in demanding environments.

Beyond aerospace, Teflon coated magnets are also revolutionizing industrial engineering. Many industrial processes involve the use of powerful magnets, which can be susceptible to wear and corrosion over time. By applying a Teflon coating, these magnets become resistant to harsh chemicals and can withstand prolonged use without compromising their performance. Industries such as manufacturing, automotive, and renewable energy are adopting Teflon coated magnets to enhance the efficiency and longevity of their processes and equipment.

As engineers continue to push boundaries, the potential applications of Teflon coated magnets seem endless. From unmanned aerial vehicles (UAVs) to medical equipment, the demand for magnets with enhanced durability and performance is only going to increase. The versatility of Teflon coated magnets makes them a promising choice for various industries, offering solutions for challenges such as high temperatures, chemical exposure, and wear resistance.

In conclusion, Teflon coated magnets are transforming the aerospace and industrial engineering sectors. Their ability to withstand extreme conditions, resist wear and chemicals, and provide reliable performance has made them indispensable in various applications. As technology progresses, the demand for these magnets is only expected to grow. Brands like BeiLun Meank have recognized the potential of Teflon coated magnets and are at the forefront of designing tomorrow by utilizing this innovation. By incorporating Teflon coated magnets in their products, they are helping shape a more efficient, reliable, and advanced future for aerospace and industrial engineering. So, let's welcome the era of Teflon coated magnets and embrace their limitless possibilities.