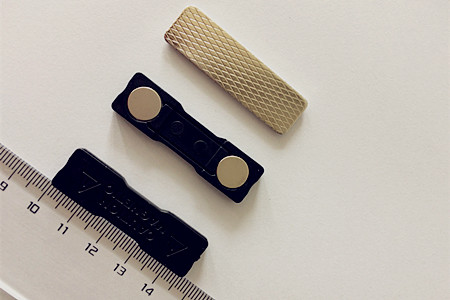

Rubber magnet is a kind of the ferrite magnet, which is a flexible and elastic magnet made by compounding bonded ferrite magnetic powder with synthetic rubber through extrusion molding, calendering molding and injection molding. It can be processed into strips, rolls, sheets, blocks, rings and a variety of complex shapes.

1. Characteristics of rubber magnets

They are flexible and elastic, and can be wound. There are rolls, sheets, strips, blocks, rings and various complex shapes.

2. Processing characteristics of rubber magnets

Rubber magnets are made by extrusion and calendaring. Rubber magnets can be bent, twisted or rolled. They don’t need more mechanical processing, and can be shaped according to the required size. The magnetic energy product is 0.60 to 1.50 MGOe.

3. Production process of rubber magnets

The production process is convenient: batching → mixing → extrusion/calendering/injection molding → processing → magnetization → inspection → packaging,.

4. Application fields of rubber magnets

Rubber magnets are widely used in daily life. They are fasteners for refrigerators, message boards to fix objects to metal bodies for advertising; they are magnetic sheets for toys, educational instruments, switches and sensors. Rubber magnets are mainly used in micro-special motors, refrigerators, disinfection cabinets, kitchen cabinets, toys, stationeries, advertising and other industries.

In formula planning, we must first determine the type, particle size and dosage of magnetic powder. Next, we should determine the type of rubber according to the requirements of use, such as natural rubber for wear-resisting drugs. During the processing, it is necessary to add magnetization process that the other products don’t have before or after vulcanization, so as to give the product permanent magnetism. The advantage of magnetization before vulcanization is that the direction of the external magnetic field is unchanged, so it can pass through the rubber network relatively smoothly; the passing ability after vulcanization is poor, but the operation is simple.

In rubber magnets, physical quantities used to characterize magnetism include magnetic intensity, residual magnetic susceptibility, magnetic energy product, etc. Magnetic intensity is the most commonly used one, and its measurement unit is Gauss (GS). Generally, rubber magnetic intensity is required to reach the range of 100 to 600 GS.

Rubber magnets are mainly divided into homogenous rubber magnets and heterogenous rubber magnets. The differences are as follows:

1. The magnetism is different: The magnetism of homogenous rubber magnets is weak, and the heterotropic rubber magnets have a higher magnetic function.

2. Working temperature and density are different. The temperature and density of homogenous rubber magnets are lower than those of heterogenous rubber magnets.

3. The application scope is different. Homogenous rubber magnets are mainly used in refrigerator magnets, car magnets, printing products, and publicity and promotion products. Heterogenous rubber magnets are widely used in fields such as micromotor computers, laser printers, photocopiers, magnetic toys, etc.

Ningbo Beilun Meank Magnetics Co., Ltd is located in the home of Neodymium-Iron-Boron magnets -Ningbo City. We're engaged in the production of rare earth neodymium magnets for over 10 years. After so many years' development in the field of rare-earth permanent magnets, we not only produce the highest grade NdFeB power magnets, but also make different kinds of magnets assemblies (such as holding magnets, rubber magnets, pot magnets, separate magnets and other kinds of magnetic tools).