As for Alnico magnets, I think many friends have never heard of it. The main reason is that this kind of magnet is relatively less involved in our daily life, less contact and less natural understanding. Here we focus on the advantages of

Alnico magnets for sale, the classification, application and machinable shape of Alnico magnets.

Let's start with its characteristics. It's an alloy made of aluminum, nickel, cobalt, iron and other trace metal elements. It has the characteristics of high energy, high induction, high residual flux density, good corrosion resistance, and high-temperature resistance.

What kinds of Alnico magnets are there? It can be divided into two categories: cast Al-Ni-Co and sintered Al-Ni-Co. The shape of cast Alnico magnets can be diversified and complicated. The mechanical dimension tolerance of sintered Al-Ni-Co can be controlled more accurately.

Next, we will talk about their applications. Cast Al-Ni-Co products are mainly used in automotive parts, instruments, electroacoustics, motors, teaching, aerospace, military, and other fields. Sintered Al-Ni-Co is widely used in electrical machinery (now gradually replaced) instruments, communications, magnetoelectric switches, and various sensors.

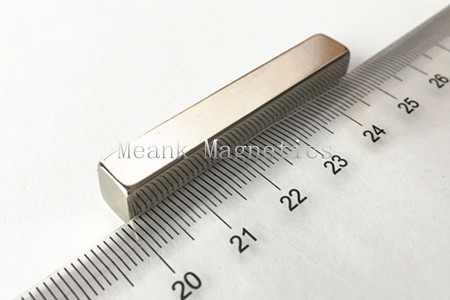

What shapes can

Alnico magnets be processed into? The shapes that can be produced are cylindrical, circular, cuboid, flat, tile and horseshoe. How do AlNi-Co permanent magnets generally be processed and manufactured? Aluminum, nickel, and cobalt permanent magnets have low mechanical strength, high hardness, brittleness and poor machinability. They can only be processed by a small amount of grinding or EDM, and can not be processed by forging or other mechanical processes.