The present invention discloses a cerium iron boron magnet alloy strip for improving coercivity and magnetic energy product. The chemical formula of cerium iron boron magnet alloy strip is Ce.

Technology background

Rare earth

NdFeB permanent magnet material has excellent performance and wide application, and the demand is increasing year by year. The cost of Nd in NdFeB takes about 90% of the total NdFeB magnets. Due to the symbiosis and limited reserves of rare earth deposits, with the increasing demand of NdFeB magnets, the price of Nd element is rising year by year, and the high abundance and low price rare earth Ce element is overstocked. Because of the poor performance of cerium iron boron magnets, NdFeB magnets application cannot be replaced by CeFeB magnets, so it is a prerequisite for the development of Ce-Fe-B magnets to improve the performance of CeFeB magnets. Therefore, a new cerium-iron-boron alloy strip is needed to solve the above problem.

Technology realization train of thought

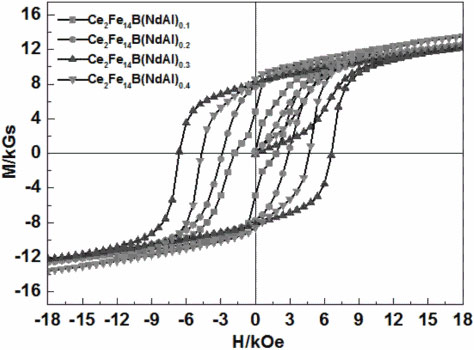

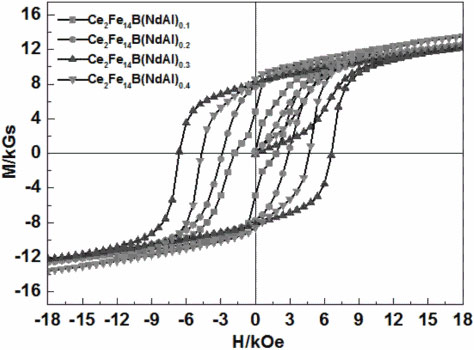

In order to solve the defects of the prior art, a kind of cerium iron boron alloy strip which can improve the coercivity and magnetic energy product is provided. In order to achieve the above objectives, the technology adopts the following technical scheme:A Ce-Fe-B alloy strip with an increase in coercivity and magnetic energy product. The chemical formula for the Ce 2Fe14 B alloy strip is Ce2Fe14B (NdAl)x, where x is 0. 1 0. 2 or 0. 3 or 0. 4.The further x is 0.3. At this time, the coercivity of the alloy strip is the largest and the maximum magnetic energy product is the highest. The magnetic properties of the Ce2Fe14B(NdAl)0.3 alloy strip are Br=8.15KGs, Hcj = (6.61) KOe, BH(max) =11.48MGOe.Further, the CeFeB alloy strip is heat-treated for 10 min-60 min at 600℃(±10 ℃). After heat treatment, enough Ce2Fe14B phase was formed, and the Ce2Fe14B phase was small enough. Enough coercivity can be obtained under the condition that sufficient remanence is formed. Further, the Ce-Fe-B alloy strip is heat-treated 20min at 600℃. After heat treatment, relatively more Ce2Fe14B phases were formed, and the grains of Ce2Fe14B phase was smaller.

Summary of technical features

1. The invention relates to a cerium iron boron alloy strip which increases the coercivity and magnetic energy product, characterized in that the chemical formula of the Ce2Fe14B alloy strip is Ce2Fe14B (NdAl)x, where x is 0. 1 0. 2 0. 3 or 0. 4.

2. The cerium iron boron alloy strip, which increases the coercivity and magnetic energy product, is characterized in that the x is 0.3.

3. The cerium iron boron alloy strip, which improves the coercivity and magnetic energy product, is characterized in that the cerium iron boron alloy strip is heat-treated for 10 min-60 min at a temperature of 600℃(±10 ℃).

4. The cerium iron boron alloy strip, which improves the coercivity and magnetic energy product, is characterized in that the cerium iron boron alloy strip is heat-treated for 20 minutes at a temperature of 600 ℃.