In today's manufacturing industry, efficiency is key. One essential component that contributes to the smooth operation of manufacturing processes is the use of magnetic balls. Magnetic balls factories, such as the renowned BeiLun Meank, play a crucial role in providing these industrial-strength materials that are vital for various manufacturing processes.

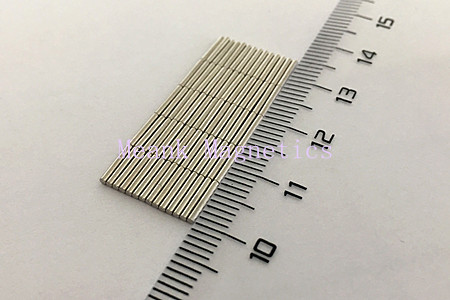

At Magnetic Balls Factory, the manufacturing process of producing these high-quality materials starts with sourcing the raw materials, such as neodymium, iron, and boron. These elements are carefully mixed together and heated to extreme temperatures in a controlled environment. Once the mixture has reached a molten state, it is poured into specialized molds, creating small, spherical magnetic balls. These balls are then cooled, polished, and inspected before being packaged for distribution.

Enhanced Precision and Efficiency

Magnetic balls are designed to have exceptional magnetic properties, making them perfect for various manufacturing applications. They provide manufacturers with precise control over their processes, ensuring accuracy and efficiency. From assembly line automation to material handling, magnetic balls offer a reliable solution.

Ease of Assembly

One of the significant advantages of using magnetic balls is their ability to assemble and disassemble products with ease. The magnetic properties of the balls allow for strong connections, eliminating the need for complex fastening mechanisms or adhesives. This not only simplifies the manufacturing process but also reduces production time and costs.

Durability and Longevity

Manufacturing processes often involve repetitive tasks, which can put a strain on the equipment and materials used. However, magnetic balls are known for their exceptional durability and longevity. They can withstand harsh conditions, high temperatures, and repeated use, making them ideal for prolonged manufacturing operations. This durability translates into cost savings for manufacturers, as they require fewer replacements over time.

Versatility

Magnetic balls factory find applications across various industries, from electronics and automotive to medical and aerospace. Their versatility allows for creative and innovative manufacturing designs. With their ability to seamlessly connect and disassemble, magnetic balls enable manufacturers to build complex structures and systems with ease.

In conclusion, the role of a Magnetic Balls Factory, like BeiLun Meank, in manufacturing processes cannot be overstated. With their precise control, ease of assembly, durability, and versatility, magnetic balls are an essential component in improving manufacturing efficiency. Manufacturers across industries rely on the exceptional properties of magnetic balls to enhance their production processes and remain competitive in today's rapidly evolving global market. Whether it's for precision engineering or heavy-duty manufacturing, magnetic balls offer the industrial strength required to elevate manufacturing processes to new heights.